| Business Type | Manufacturer, Exporter, Supplier |

| Material | Alloy Steel |

| Surface Finishing | Rough Turned,Peeled |

| Color | Silver |

| Click to view more | |

Product Details

AISI 4330V – description

High strength steel used in applications involving shock loading or stress concentration, for example drilling jars in oil and gas sectors or air frames and fasteners in aerospace industry. AISI 4330V is basically AISI 4330 steel with strength and hardenability improved by the addition of vanadium. The type of 4330 steel with a significant addition of nickel is called "4330 mod."

AISI 4330V STEEL FORGING

• Initial Forging Temperature:1150-1200°C

• Final Forging Temperature:>850°C

• Heating Rate:Strictly control the heating speed, which should be uniform and stable to

prevent cracking caused by improper heating.

• Holding Time:Ensure that the material is fully and evenly heated,and the holding time

should not be too long or too short.

• Forging Ratio:above 4:1

• Post-Forging Treatment:According to our experience, 4330V steel has extremely high

sensitivity to white spots, so dehydrogenation annealing after forging is a necessary heat treatment process.

AISI 4330V STEEL HEAT TREATMENT

• Normalizing:900-920°C,Cool in air.

• Annealing:830-860°C,Cool in furnace,Hardness Max 241 HBW.

AISI 4330V STEEL SUPPLY FORM & SIZE & TOLERANCE

- Hot Forged Round bar:Φ80-Φ1000mm

- Hot Rolled Round bar:Φ16-Φ160mm

- Heat treatment:Quenched and Tempered (+QT), Normalizing (+N), Annealing (+A)

- Surface finish:Black / Rough turned / Peeled

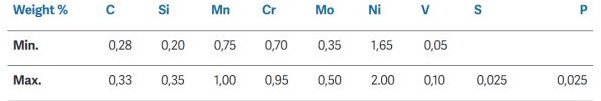

Chemical Composition

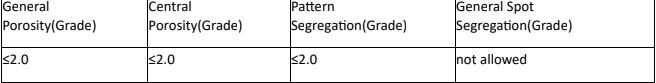

Macroscopic structure

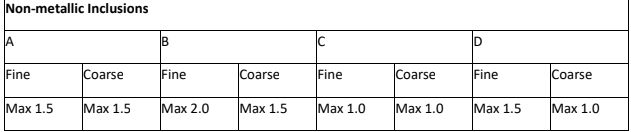

Non-metallic Inclusions

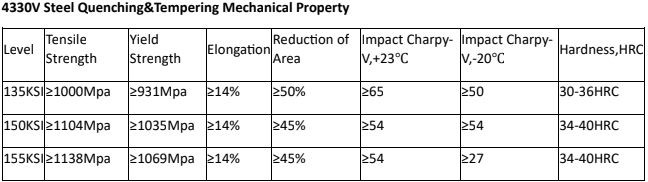

4330V Steel Quenching&Tempering Mechanical Property